| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : GHE

Model Number : ET and CT SERIES

Certification : 9001

Place of Origin : CHINA

MOQ : 1 piece

Price : USD 1000-10000 /per piece

Payment Terms : L/C, T/T

Supply Ability : 5000 pieces /year

Delivery Time : 15 work days

Packaging Details : Wooden package

Shell Material : Carbon steel

Tube material : Copper ,Stainless Steel

Customized Available : Yes

Warranty : 1 year

Condition : New

application : Refrigeration

Machinery test report : Provided

Video outgoing inspection : Provided

shell tube heat exchanger as Flooded Evaporator in refrigeration system

Flooded Evaporator is a high eficiency part for the whole system ,Flooded screw water cooling chiller is advanced for big cooling capacity ,usually like in HVAC ,in central building cooling

Features:

The structure of Shell-tube heat exchanger is strong, we can choose a variety of materials in manufacturing, adaptability is extremely strong, especially widely used in high temperature, high pressure and large devices .

Typical Application

Evaporator in Screw chiller system

Dry shell and tube evaporators are mainly used in Freon refrigeration systems. The refrigerant liquid of this kind of evaporator goes on the tube side, so the refrigerant charge is less. Its structure is similar to that of the flooded evaporator, the difference is that a number of circular baffles with arcuate area cut off and arranged upside down are set on a plurality of horizontal smooth copper tubes. After throttling, the refrigerant liquid enters the tube side from the inlet below the end cover of one end of the evaporator. After absorbing heat in 2-4 processes, it is led out from the outlet above the end cover on the same side. The flow of refrigerant in the shell-and-tube type dry evaporator has different forms such as single-in and single-out, double-in and single-out, and double-in and double-out. The cooling tube is usually a copper tube with an outer diameter of 12-16mm. There are longitudinal fins in the tube. The mass flow rate in the tube is generally 180-200 kg/(nf-s), and the number of partitions should ensure that the coolant flows laterally. The speed of the tube cluster is 0.5—1.5 m/so

The advantages of dry evaporators are: ① less liquid filling, which is about 40% of the inner volume of the tube; ② less affected by the static pressure of the refrigerant liquid; ③ easy to drain oil; ; ⑤ The refrigerant level is easy to control; ⑥ The structure is compact; ⑦ The heat transfer coefficient is high. The disadvantage is that the liquid supply of the refrigerant in the tube group is not easy to be uniform, the manufacture and installation of the baffle plate is more troublesome, and between the tube hole and the tube of the baffle plate on the refrigerant side, and between the outer circumference of the baffle plate and the shell, leakage bypass flow is easy to occur. , thereby reducing the heat transfer effect.

Condenser in Screw chiller system

GHE provide customers in HVAC and refrigeration industries with quality and stabilization shell tube evaporators ,we help customer to create value with our honest attitude and competitive price .

GHE provide customers in HVAC and refrigeration industries with quality and stabilization shell tube evaporators and condenser,we help customer to create value with our honest attitude and competitive price .

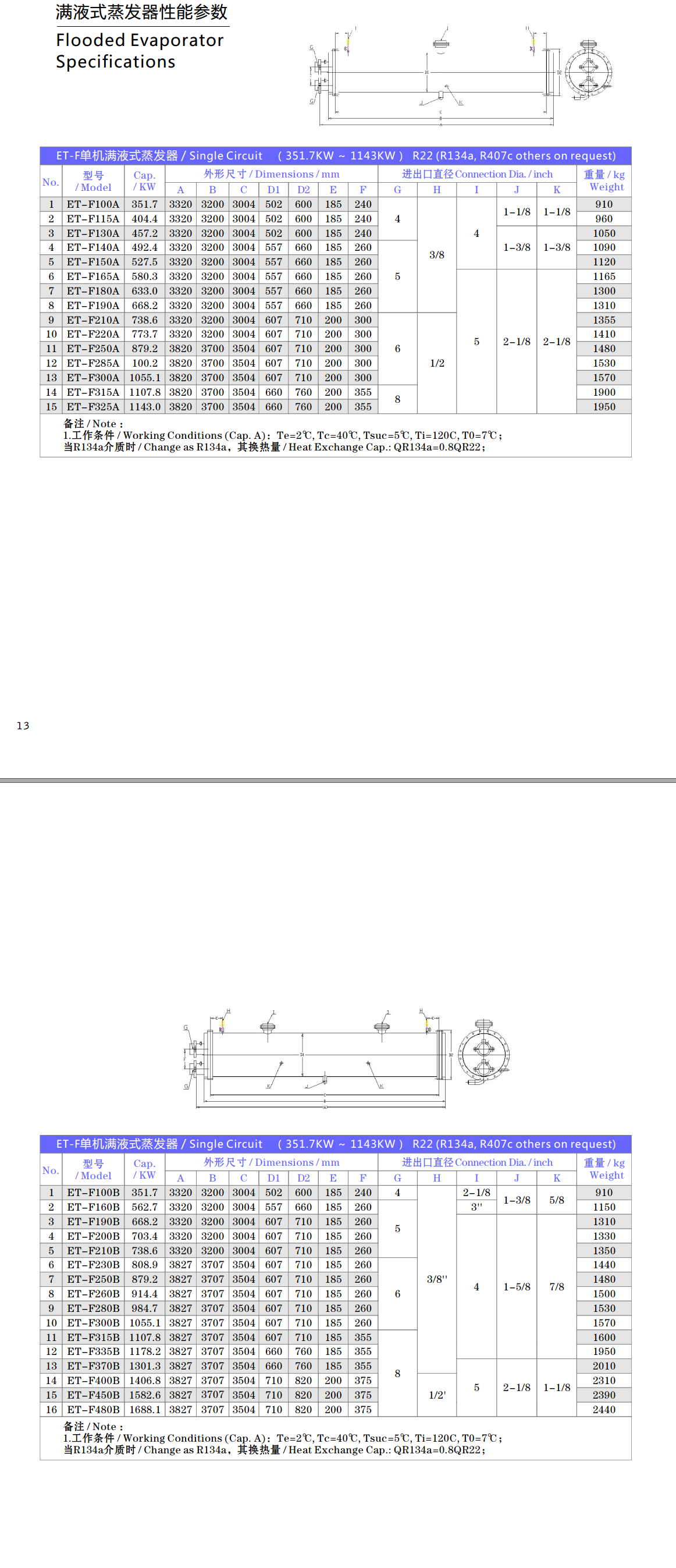

Flooded Evaporator Specifiation

The quality will be beyond your imagination

Payment Terms

|

|

1000kw Shell Tube Heat Exchanger Brazed Flooded Evaporator In HVAC Screw Refrigeration Equipment Images |